Article No. : 19

My Bio & Scientific Articles [HERE]

INDEX

- Introduction.

- Overview of Maritime Transportation.

- Trains Technologies Nowadays.

- Hyper-Loop Technology inside Water.

- The Concept of Oceanic Train Technology.

- Classification of Oceanic Tunnel.

- Engineering Analysis of the Oceanic Tunnel.

- Challenges of Oceanic Train Technology.

- Recommendations.

- References & Websites.

1) Introduction:

No doubt, that having reliable efficient high speed transportation vehicle either in land, on air or cross vast ocean is economical advantage for travelling or shipping freights/goods to distant countries.

Ships are an optimal option for transported many heavy goods by approximately 80% of the international trading, but it has an expensive cost to ensure the quality of certain products, such as some types of foods & drugs which may changed their physical & chemical properties along the time, if it’s doesn’t have enough cooling & humidification systems inside the ships.

That’s will definitely will increase the operational cost of transportation, which it has a direct proportional relationship with the time of transportation by using slow moving vehicles such as ships or submarines.

I came-up with this extraordinary idea since 2019 & I intend to write about it immediately, until someone that I knew him for long time stopped me. He was a brilliant scientific inventor & patent attorney from foreign country. He advised me to not publish this kind of article in public. I was convinced about his argument to find something else & discuss it with him. So, I give-up from that idea temporarily & thinking about another one.

I have decided to find way to improve the regular speed of ships, and we both really have an excellent conversation about it for more than 10 ideas that I came up with it, especially how to solve the “Cavitations Effect” which let us to increase the payload of ships by using similar design of airfoil (Wing) which is used in planes. It’s named as “Hydrofoil” if we are using it in water. Of course, the speed of ship will increase if want to keep the old payload as same as catalogue of ships manufacturer said.

Anyway, I decided to return back to my old idea of oceanic train, as my scientific passion prevent me to stop thinking & my mind can’t let go away at all. I was really missing to write articles after all these months without doing thing. It’s like “The Nostalgia”.

It’s my comfortable zone that I feel safe, warm, happy & self-confident about what I’m doing.

*

Now, let us ask our self one question;

Is It Worth to Build A Long Tunnel On Ocean?

Freight transportation is the commercial transport of goods. Most of the products and goods which make up our daily lives originate from somewhere else. These global patterns of production and movement of goods reflect an increasingly interconnected and complex world of commerce. Although trucks, trains and planes are frequently a barely noticed background noise of modern life, freight transportation has significant economic, environmental and societal implications. [Ref-1]

Let us assume that we want transport 1 Ton of shoes from point ‘A” to “B” which is proposed to be 1000 miles by using different types of transporter such as ship, train, truck & plane as we see in figure (6).

The technical specification of the average speed & fuel consumption of each transporter are mentioned in figure (7).

So, by using above specification, we may find the time of arrival for 1000 miles & the required quantity of fuel. Figure (8) shows the result of our calculation.

The plane is the fastest (time), and the ship is the most fuel efficient (required quantity of fuel). The train might be the best combination of both, using these calculations.

Extenuating circumstances could be the costs of the different types of fuel or that the actual distance travelled by each means may be very different due to weather, flight patterns, existing rail lines, roads and traffic. In addition there are other costs to be considered such as labor and infrastructure costs.

The train may be the best transportation choice for the shoes. Cargo that is time sensitive or may expire may need to be shipped in the fastest as opposed to most fuel efficient manner.

The pros and cons of each transportation option can vary when additional factors are addressed, such as: road and rail maintenance and construction, weather, traffic, labor needs, flexibility, needing to be in bulk quantities, infrastructure needs (airports, seaports, train stations), wildlife impacts, etc.

The question of environmental impact is to set up the next activities about carbon and intermodal shipping. There is an assumption that the less fuel that is used is better for the environment. However there can be additional environmental impacts beyond the impact of carbon emissions such as the environmental impact of the infrastructure (roads, rails, shipyards) needed for the transportation of cargo, and even how freight transportation choices can affect how areas are developed. Avoid coming to definitive conclusions because each choice has impact; simply discuss different possible ways to measure the environmental impact. Brainstorm the many types of environmental impacts for instance, water quality issues or noise pollution, and consider what types of environmental impacts may be more significant than others. [Ref-1]

From what we see previously, the answer of what good or wrong is difficult & complex due to many factors involved such as; speed of delivery, cost of shipping and delay/damage risk as well as considerations such as environmental impact, which may affect in our decision of the method for transportation as each type have its own advantages & drawbacks.

So, extensive studies should be made for using tunnel on ocean. This article will be like a introduction for professional people to think about what can the maritime industry become in the future.

#

2) Overview of Maritime Transportation:

- Market Potential:

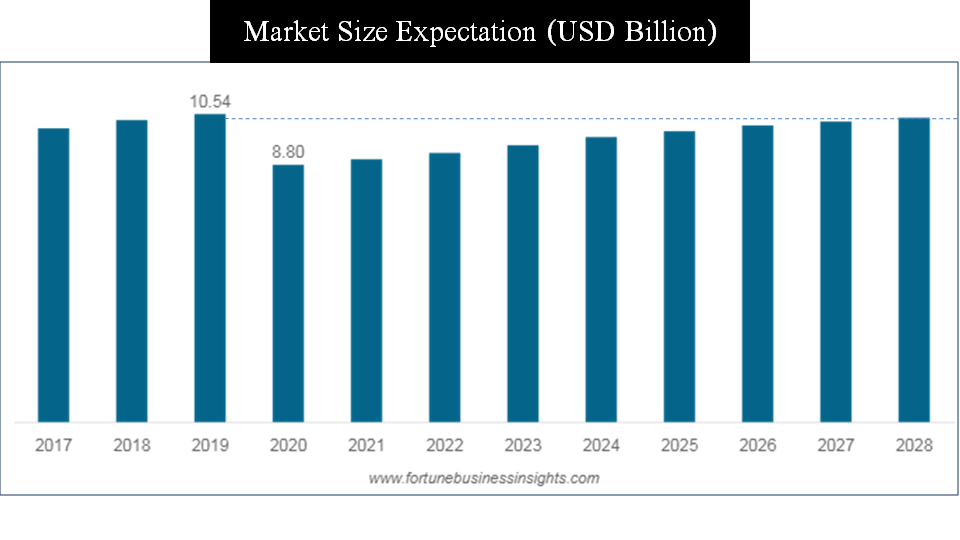

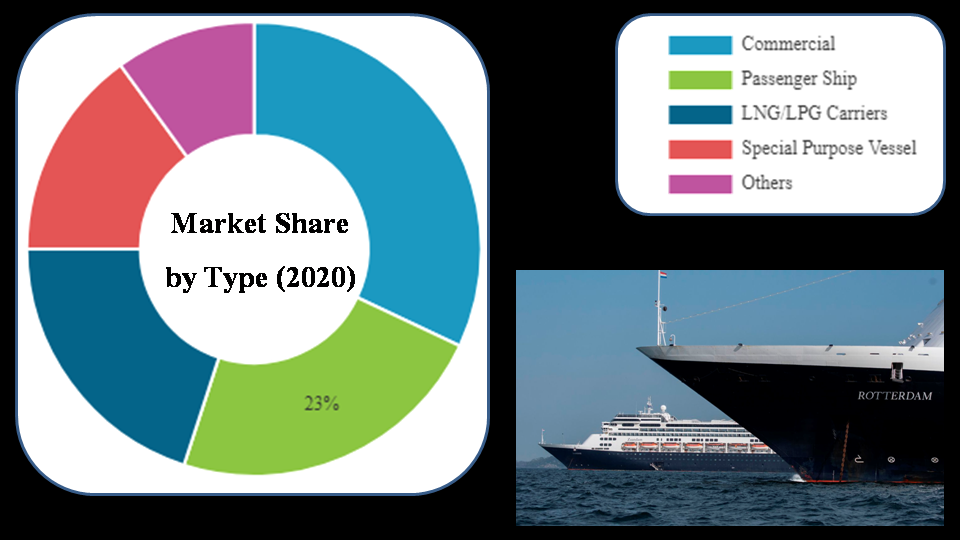

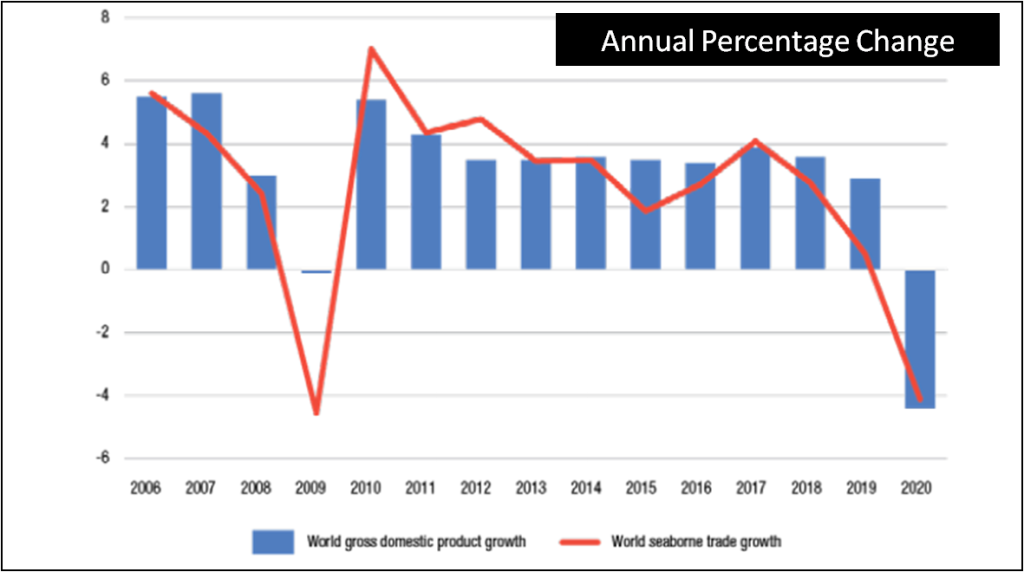

It has been estimated the global marine vessel market size was 168.56 billion USD in 2020.

Surge in Global Sea Trade is expected to Increase Demand for Product Maritime transport is the pillar of international trade and the global economy. A rise in seaborne trade across the globe is expected to fuel the growth of the market during the global marine vessel industry forecast period. According to Maritime Publications, around 80% of the global trade by volume and over 70% of the global trade by value are carried out by sea and are controlled by ports worldwide. Globalization and the rapid expansion of Asian economies, such as China and South Korea, would play a major role in maritime trade growth.

The global impact of COVID-19 has been unprecedented and staggering, with marine vessels witnessing a negative demand shock across all regions amid the pandemic. Based on our analysis, the global market had shown a decline of 17.2% in 2020 as compared to the average year-on-year growth during 2017-2019. The market is projected to grow from USD 170.75 billion in 2021 to USD 188.57 billion in 2028 at a CAGR of 1.43% in the 2021-2028 period.

The market is dependent on the volume of the global maritime trade and the shipping demand. The performance of international markets influences both. The demand for ships increases during economic growth and decreases during the recession.

As stated by the United Nations Conference on Trade and Development (UNCTAD), around 80% of the global trade by volume is carried out by the sea. Therefore, it is clear that maritime transport is an engine of the global trade and economy that closely follows the GDP growth of the nation. The market is anticipated to propagate at a slow but steady pace during the forecast period. [Web-1]

- Pandemic Effect of Covid-19:

The corona-virus disease (COVID-19) pandemic has underscored the global interdependency of nations and set in motion new trends that will reshape the maritime transport landscape. The sector is at a pivotal moment facing not only immediate concerns resulting from the pandemic but also longer-term considerations, ranging from shifts in supply-chain design and globalization patterns to changes in consumption and spending habits, a growing focus on risk assessment and resilience-building, as well as a heightened global sustainability and low-carbon agenda.

The sector is also dealing with the knock-on effects of growing trade protectionism and inward-looking policies. The pandemic has brought to the fore the importance of maritime transport as an essential sector for the continued delivery of critical supplies and global trade in time of crisis, during the recovery stage and when resuming normality.

At the beginning of 2020, the total world fleet amounted to 98,140 commercial ships of 100 gross tons and above, equivalent to a capacity of 2.06 billion dwt [Dead Weight Tons]. In 2019, the global commercial shipping fleet grew by 4.1 per cent, representing the highest growth rate since 2014, but still below levels observed during the 2004–2012 period.

Gas carriers experienced the fasted growth, followed by oil tankers, bulk carriers and container ships. The size of the largest container vessel in terms of capacity went up by 10.9 per cent. The largest container ships are now as big as the largest oil tankers and bigger than the largest dry bulk and cruise ships. Experience from other ship types and limitations affecting access channels, port infrastructure and shipyards, suggest that container ship sizes have probably reached a peak.[Ref-2]

- Initiatives to Reduce Carbon Emissions from Shipping:

Member States of International Maritime Organization (IMO) agreed in 2018 “to reduce the total annual greenhouse gas emissions by at least 50 per cent by 2050 compared with 2008” as part of the Initial IMO Strategy on reduction of greenhouse gas emissions from ships. To help achieve this objective, the International Chamber of Shipping and other maritime industry associations propose the establishment of a research and development fund to help cut emissions.

For heavy fuel oil, this would correspond to a carbon price of $0.63 per ton of carbon dioxide. The project would raise about $5 billion over 10 years. This fund is to be financed by a contribution of $2 per ton of marine fuel oil purchased for consumption. The private sector-led Getting to Zero Coalition suggests that “Shipping’s de-carbonization can be the engine that drives green development across the world”.

The falling costs of net zero-carbon energy technologies make the production of sustainable alternative fuels increasingly competitive. Determined collective action in shipping can increase confidence among suppliers of future fuels that the sector is moving in this direction.

United Nation Conference on Trade and Development (UNCTAD) supports the Getting to Zero Coalition and promotes efforts to achieve sustainability, helping developing countries adapt and build resilience in the light of the climate emergency.

According to Parry et al., 2018, “The environmental case for a maritime carbon tax is increasingly recognized”. According to the Environmental Defence Fund (2020), “meeting the IMO’s 2050 target represents $50 billion to $70 billion per year for 20 years’ spending, but this is also a revenue opportunity”. Englert and Losos, 2020 [from the World Bank], also a supporter of the Getting to Zero Coalition, state that a large share of this investment opportunity could lie in developing countries. A sizable part of these investments will have to be made ashore, including in energy infrastructure and in seaports.

Ship-owners will have to invest in the renewal of the fleet and new technologies. Engine power limit is a short-term measure proposed by Japan that would enable ship-owners to meet requirements relating to the energy efficiency index for existing ships and to reach the IMO target in 2030.

Engine power limit decreases vessel speed with minimal changes in ship performance, thus reducing fuel use and emissions based on the cube law (relationship between engine load and vessel speed).

In a recent study, the systematic assessment of vehicle emissions model of the International Council on Clean Transportation is used to evaluate different scenarios of engine power limit focusing on container ships, bulk carriers and oil tankers, with 2018 automatic identification system data being utilized as a baseline. The study argues that carbon-dioxide “reductions will not be proportional to engine power limit because ship engines are already operating far below their maximum power”.

This model shows the negligible effect of engine power limit of less than 20 per cent on a ship’s carbon-dioxide emissions. As for an engine power limit ranging between 30 and 40 per cent, emissions reduction is between 2 and 6 per cent. However, the study shows a significant reduction of carbon-dioxide emissions (by 8–19 per cent) for a larger engine power limit of 50 per cent or more.. [Ref-2]

- Shift from Conventional Propulsion to Hybrid Propulsion System is a Prominent Trend:

Huge marine vessels consume a large amount of fuel and thus contribute to global warming. However, fuel is the main cost factor for many shipping companies. Hence, improving energy efficiency is the main driver for innovation in the shipping industry.

The switch from the fuel-based conventional propulsion system to the environment-friendly hybrid propulsion is increasing owing to the efficiency and cost-effectiveness of the hybrid propulsion system. Many ship operators use renewable energy, such as solar energy, as a storage option in marine hybrid propulsion systems. In this system, the stored solar energy is utilized during peak hours or at night, reducing the 24X7 need for conventional marine fuel. Moreover, strict regulations associated with reducing harmful carbon emissions have increased the demand for hybrid propulsion systems. [Web-1]

*

3) Trains Technologies Nowadays:

In rail transport, a train is a series of connected vehicles that run along a railway track and transport people or freight. The word train comes from the Old French trahiner, derived from the Latin trahere meaning “to pull, to draw”. Trains are typically pulled or pushed by locomotives (often known simply as “engines”).

Trains have their roots in wagonways, which used railway tracks and were powered by horses or pulled by cables. Following the invention of the steam locomotive in the United Kingdom in the early 1800s, trains rapidly spread across the world, allowing freight and passengers to move over land faster and cheaper than ever possible before. [Web-2]

The first full-scale working railway steam locomotive was built in the United Kingdom in 1804 by Richard Trevithick, a British engineer born in Cornwall. This used high-pressure steam to drive the engine by one power stroke [Web-3]

Rapid transit and trams were first built in the late 1800s to transport large numbers of people in and around cities. In the mid–20th century, diesel and electric locomotives replaced steam as the means of motive power. Following the development of more flexible cars and faster airplanes, trains declined in importance and market share, and many train lines were abandoned. The spread of buses led to the closure of many rapid transit and tram systems during this time as well. Since the 1970s, governments, environmentalists, and train advocates have promoted increased use of trains due to their greater fuel efficiency and lower greenhouse gas emissions compared to other modes of land transport.

High-speed rail, first built in the 1960s, has proven competitive with cars and planes over short to medium distances. Commuter rail has grown in importance since the 1970s as an alternative to congested highways and a means to promote development, as has light rail in the 21st century. Freight trains remain important for the transport of bulk commodities such as coal and grain, as well as being a means of reducing road traffic congestion by freight trucks.

While conventional trains operate on relatively flat tracks with two rails, a number of specialized trains exist which are significantly different in their mode of operation. Monorails operate on a single rail, while funiculars and rack railways are uniquely designed to traverse steep slopes. Experimental trains such as maglevs, which use magnetic levitation to float above a guide-way, are under development in the 2020s and offer higher speeds than even the fastest conventional trains. Development of trains which use alternative fuels such as natural gas and hydrogen is another 21st century development. [Web-2]

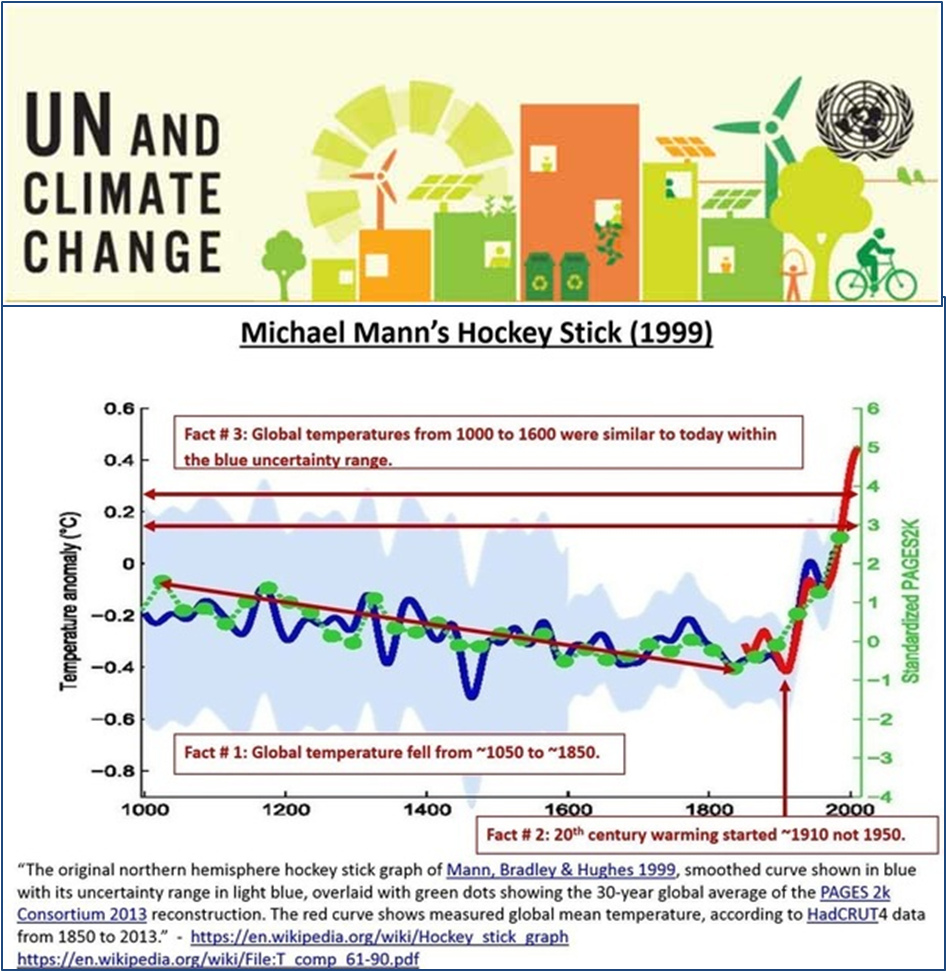

Some of trains nowadays are still works by using coal & woods as fuel for operation in many developing countries & that’s definitely will effect negatively on the objectives of COP UN-Climate Change to reach earth temperature of 1.5°C in 2050 after they changed from temperature 2°C for some political & economical reasons.

But with the progression of science & technology, we’ve been able to invent new types of train which differ from old ones & they used electricity or bio-fuel instead of traditional fossil fuel.

The trains technology is classified according to the famous mechanism of operation (or the motive of power) are:

- Steam Locomotives: It works by using a boiler to heat water into steam, which powers the locomotive’s pistons which are in turn connected to the wheels. [The average speed of this type is around 201 km/h (125 mph) & it has been recorded in London North Eastern Railway 'Class A4' No. in Dec 31, 1969]. Steam locomotives are still used in heritage railways operated in many countries for the leisure and enthusiast market.

- Diesel Locomotives: They are powered with a diesel engine, which generates electricity to drive traction motors. This is known as a diesel–electric transmission, and is used on almost all diesels. Diesel power replaced steam for a variety of reasons: diesel locomotives were less complex, far more reliable, cheaper, cleaner, easier to maintain, and more fuel efficient. [The average speed is around 238 km/h (148 mph), and it was set by an HST on 1 November 1987].

- Electric Locomotives: Electric trains receive their current via overhead lines or through a third rail electric system, which is then used to power traction motors that drive the wheels. Electric traction offers a lower cost per mile of train operation but at a higher initial cost, which can only be justified on high traffic lines. [This type of train may have speed between 300–350 km/h (190–220 mph)].

Various other types of train propulsion have been tried, some more successful than others. In the mid 1900s, gas turbine locomotives were developed and successfully used, though most were retired due to high fuel costs and poor reliability.

In the 21st century, alternative fuels for locomotives are under development, due to increasing costs for diesel and a desire to reduce greenhouse gas emissions from trains. Examples include hydrail (trains powered by hydrogen fuel cells) and the use of compressed or liquefied natural gas (CNG/LNG). [Web-2]

*

4) Hyper-Loop Technology inside Water:

The hyper loop concept in simple words (without boring us in detail) is a low pressurized tunnel which let us to reduce the drag force on capsule (vehicle) & it able to increase its speed up to 1200 Km/h (747 MPH) similar to the speed of commercial planes. It has been invented by the famous brilliant entrepreneur “Elon Musk” who is also the founder of “SpaceX” & “Tesla” company.

Video 1 of Hyper-Loop Technology: [LINK1 – LINK2]

Definitely, the construction cost is very high as we should maintain low pressure of air inside tube for ever over a long path of trip & that’s mean we should make sure that there is not any leakage of air inside the hyper-loop tube. It will not explode if there is a leak, but it will decrease the speed of capsule which effect negatively on the reputation & economical side of the company. Without forget that it should be monitored 24H/7W (around clock) to avoid any intention of property damaging form who don’t like it as it made from concrete, reinforced with steel and carbon fiber, especially if you’re planning to implement it in a military conflict zones that it may have a higher probabilities to happen in nearest future.

Using hyper-loop technology inside water was an idea came up with some engineers & researchers from Netherland as they want hi-speed transportation method rather than using slow ships & Musk’s concept may be the key for their project to success.

Video of Hyper Loop inside water: [LINK]

Maritime Research Institute Netherlands (Marin) is testing a model for a trans-Atlantic underwater tunnel capable of supporting a hyper-loop system.. The 140 meter (460 foot) model tunnel is being tested in one of the research organization’s basins to see how it responds to wave action. This will determine if the hyper-loop pods can travel safely inside the tunnel under real oceanic conditions. The actual tunnel would be around 5,500 kilometers (3,400 miles) long at a depth of over 100 meters (328 feet) with 30-meter (98-foot) pods capable of carrying 60 people. The pods would travel at 1,000 kilometers per hour (620 miles per hour) – essentially without air resistance or friction as they moved along the vacuum-sealed tunnel.

The Marin researchers say this mode of transport offers a less polluting alternative to air travel, and they hope to form a consortium to develop the concept.[Web-4]

Anyway, it’s only the beginning to figure out the pros & cons of hyper loop technology underwater. What we will talk about oceanic train technology is a little bit different from the concept of Musk’s Capsule.

#

5) The Concept of Oceanic Train Technology:

The purpose of this article; is to find ways to transport commercial goods via seawater faster than the traditional method (i.e. ships & submarines). So, it’s not necessary should be a train with multi-trucks. It can be also single truck or an electric convey system along the maritime road between two locations. The term of “Oceanic Train” is only a hypothetical term for describing a large continues quantity of logistics supplies.

The oceanic train technology is contains of:

- The vehicle.

- The tunnel.

- The foundation.

- Observation Point Platforms.

The Vehicle:

As we said previously, it shouldn’t necessary to be a long train, as it can be small car or trucks, if the transportation via plane is too expensive compared to the maritime type.

We can introduce another new type of vehicle which depend on convey things similar to the factory which may be named as “Oceanic Electric Conveyor System”. It can be considered as a small autonomous train to transport specific goods effectively & quickly which can be controlled from remote control center in the end of oceanic road.

Ok, from where do we get the electricity?

That the awesome part of the oceanic train technology.

We can utilize from renewable energy technologies such as solar, wind & ocean energy by putting their devices & equipments along the oceanic road. We will discuss how it can be done in next chapters because not all types of tunnel can used for that.

The Tunnel:

It’s considered as the vital component of the technology which all other elements is depend on it.

The oceanic tunnel should be made of a material which has characteristics to sustain:

- The heavy weight of vehicles (e.g. train & trucks) with its payloads and,

- The harsh environment of ocean (e.g. high humidity, salinity of water, ocean waves, storms & dangerous big sea animals such as whales & sharks)

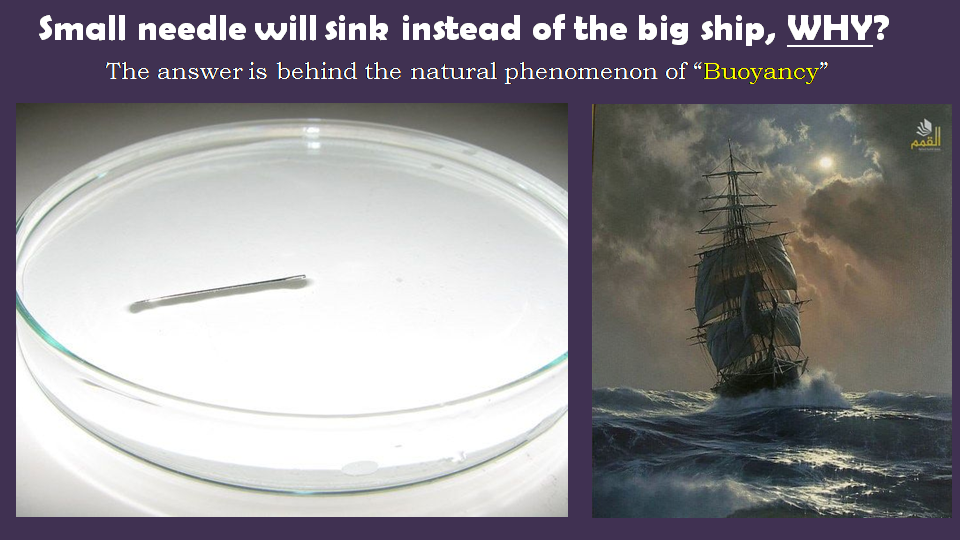

We may understand how Archimedes principle of buoyancy works, and the obvious example was being taught us always in the school, that needle will sink in the water, but big ship will not.

The reason behind that is we have created a reverse force which acted opposite to the gravity force. That force named as “Buoyancy Force” & it does depend on the swept volume from water when the object put it on the water. These 2 forces of gravity & buoyancy may be described as equations (1) & (2):

Where:

- mo : The original mass of object (Kg)

- g: Gravitational acceleration (m/s2)

- ms : The swept mass from water by object (Kg)

- ρs : The hypothetical density of swept object (Kg/m3)

- Vs : The swept volume from water by object (m3)

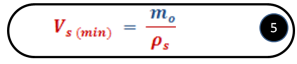

By equalizing equation (1) with (2), the minimum swept volume for making object float will be:

Let us examine the last equation with the situation of Why the needle is sinking into the bottom of water basin always?

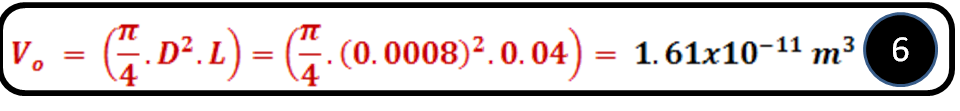

Let us assume that our needle has these physical properties & by assuming it has cylindrical shape:

- Material: Steel

- Density (ρ): 7860 Kg/m3

- Length (L): 4cm

- Diameter (D): 0.8mm

Firstly, we calculate the original volume of needle as we see in equation (6):

So, the original mass of needle is calculated by using equation (7):

Now, we find the minimum volume for the needle to avoid sinking, by using equation (5) & we get:

As you notice from results of equation (6) & (8), the original volume of needle (1.6×10^-11) is less than minimum volume for floating (1.26×10^-10). So, it will naturally sink in the bottom of water basin.

We notice that the minimum volume to prevent phenomenon of sinking from happening naturally, is by increase its volume greater than the minimum swept volume.

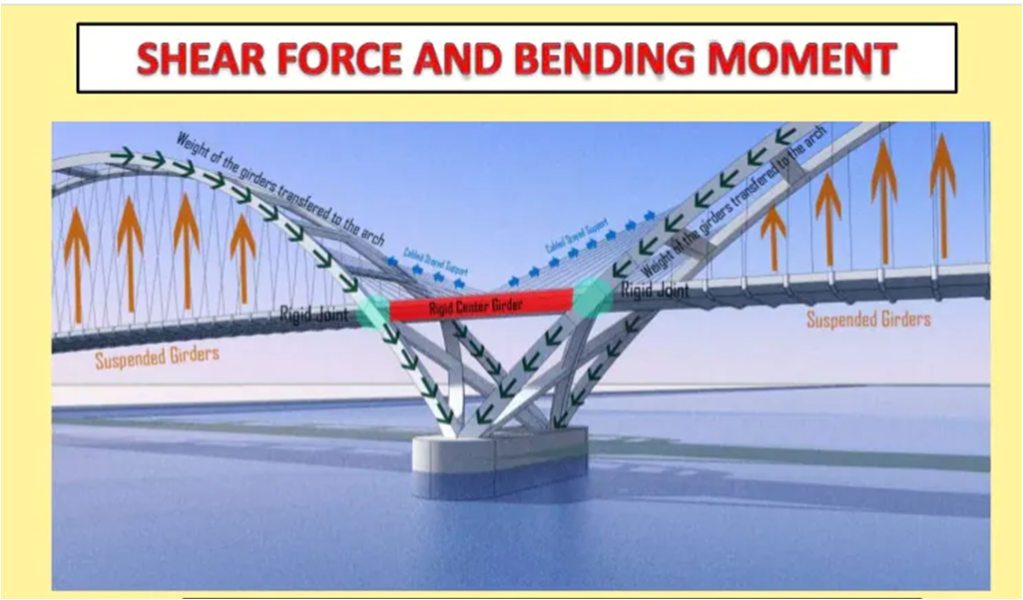

Actually, when we discuss the size of oceanic tunnel, it’s more complicated rather than the case of needle; because we are not facing only the gravity & buoyancy force only. There will be the bending & shear force as we see in figure (30) due to ocean motion. It’s similar to what civil engineers faced when they want to design & build a bridge between 2 points. Many factors should be considered especially the strength of the material for oceanic tunnel.

The frontal tunnel may have different shapes depend on the situation that we face on the seawater as we see in figure (31).

The oceanic tunnel may be either open or closed tunnel. We will discuss this matter in the next chapter.

The Foundation:

You are in water, and you know that everything around you will be move randomly somehow and it may be broken if it’s not fixed well by strong storm. The purpose of oceanic foundation is to make sure that tunnel will not move a lot or to be destructed by natural events such as the storm.

There are many types of oceanic foundation may be used like; the anchor, oceanic columns or a hybrid of them.

The foundation may be designed also similar to the civil structure of building to reduce the cost of construction & definitely it should be polished by anti-corrosion paint.

Observation Point Platforms:

Precautions should be priority No.1 in risky environment.

The remote survey center has noticed that it happened unexpected accidents in specific part of oceanic tunnel which is required them to fix it quickly by sending the maintenance team, but what if the teams is in the land already & we have 5 minute only before the disaster happen & destroy that part of tunnel which lead to stop goods traffic for months. It’s really big problem.

One the solution for that problem is to establish what can be called “Observation Platforms” along the tunnel in specific distance to handle such kind of emergency situations when it’s happening. It’s very similar to the oil rig sea-water platform as we see in figure (34).

Also, if the train or truck has stopped in the middle of oceanic tunnel & we decided to activate the evacuation plan to remove the train from the tunnel. This team on the observation platforms may help them. There will be an Evacuation ship stand-by for emergency situation in every observation point platform.

#

6) Classification of Oceanic Tunnel:

There are many designs for the oceanic tunnel depends on many factors such as the water-depth, climate & storm conditions, political disputes, military conflicts in the area & economical advantages. The oceanic tunnel may be classified as:

- Surfaced Tunnel.

- Hanged Tunnel.

- Deep Tunnel.

- Under-Water Tunnel.

- Above-Water Tunnel.

***********

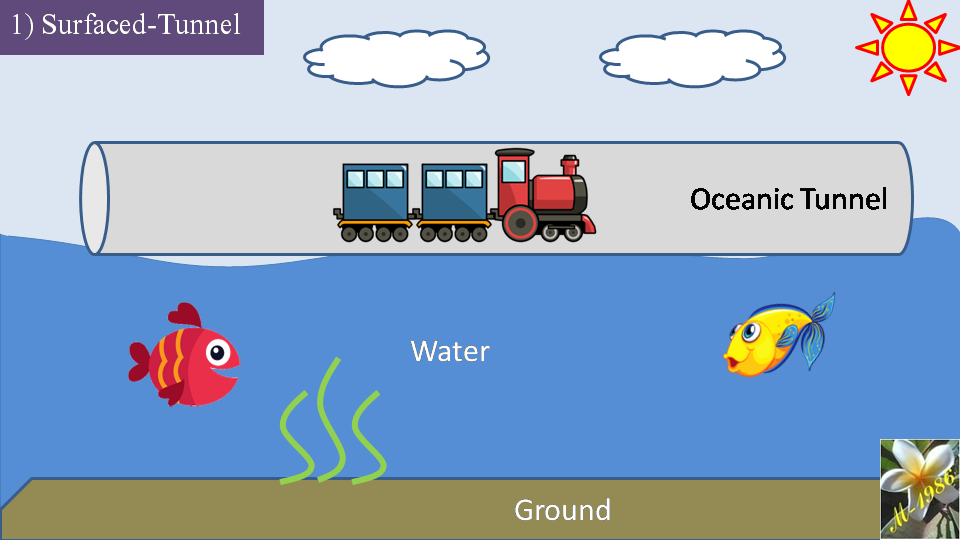

_(1) Surfaced Tunnel:_

It’s a type of tunnel that floats on the surface of seawater as we see in figure (35). It very similar to have a chain of ships aligned horizontally along the maritime road. Definitely there will be special gates in different locations to allow ship to cross it to other side for some reason such as maintenance services for the oceanic tunnel.

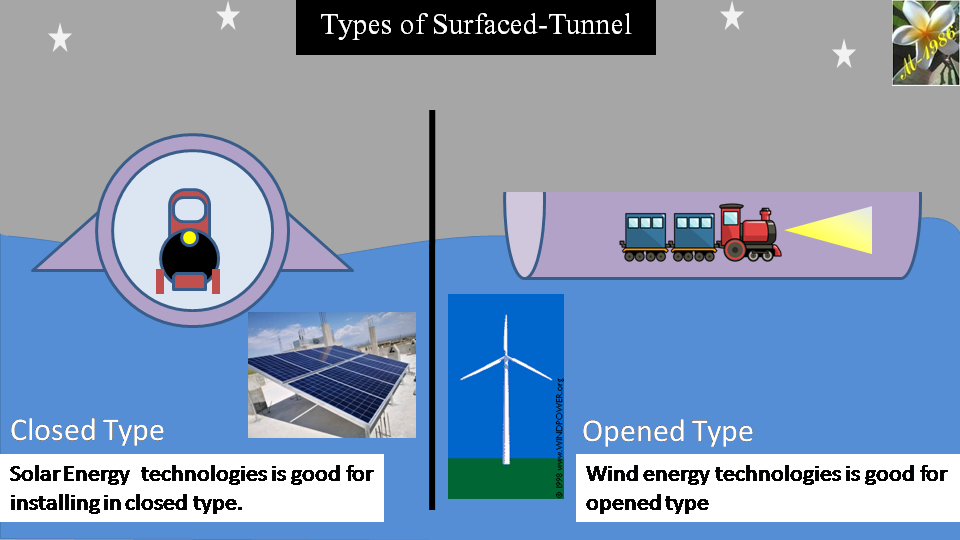

There are 2 design related to this type of tunnel; Opened & Closed Surface Tunnel.

The main difference between them, that open type doesn’t have an upper cover on it& it’s simple for construction which may reduce the cost of material, in opposite to the closed one which has a ceil to prevent unwanted natural accidents.

So, what are you meaning by “Unwanted Natural Accidents”?

In previous chapter, we talking that we may use “Renewable Energy Technologies” to produce electricity.

Wind energy devices may be good choice for the open type as it will be like a window in home & solar energy devices should be mounted in closed types to prevent precipitation of the salty water if the wave is too strong (i.e. storm).

This type of tunnel is very cheap compared to other types but easy for construction & maintenance services. It can be used for other purposes such as tourist, fishing zones or scientific researches for individuals & researchers. Even we can build a floated–hotel.

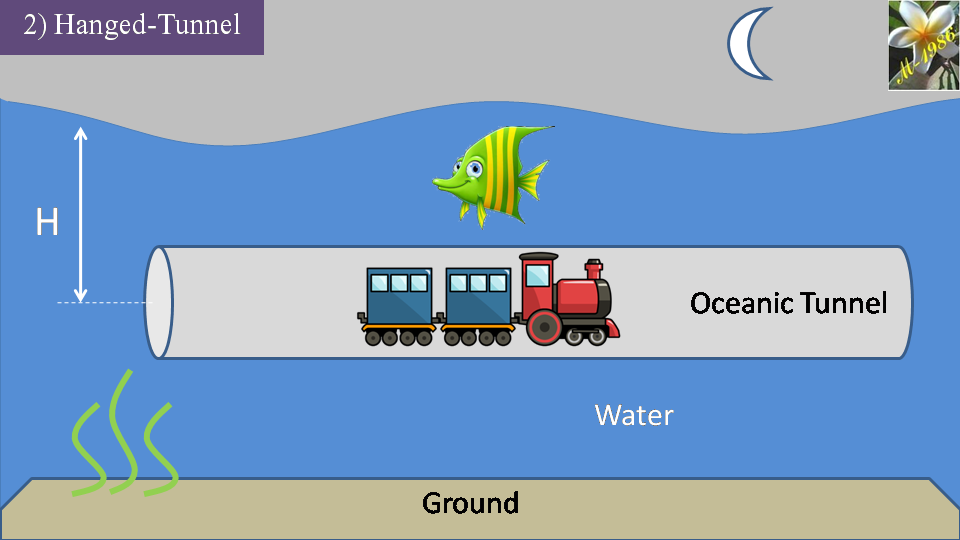

_(2) Hanged Tunnel:_

Surfaced tunnel may have some weakness due to the existence on the sight of human which leads to be vulnerable to damage by any persons who hates the oceanic tunnel concept as it effects his/her business. Also, it may prevent an easy-access to the port for fishing boats & oil ships/tankers in daily-basis.

So, designing of hanging tunnel may be an alternative option to solve the previous issues as we see in figure (37). “H” is represent the Depth of tunnel from the sea-water level, which is very important for engineering analysis to know the cost of construction & we will discuss it later. Simply of speaking, It let us to determine a suitable material for the tunnel in that position which can sustain the high pressure of water & if the “Depth” is increased, the construction cost of tunnel will increased eventually, but the risk of damage by human will reduce simultaneously.

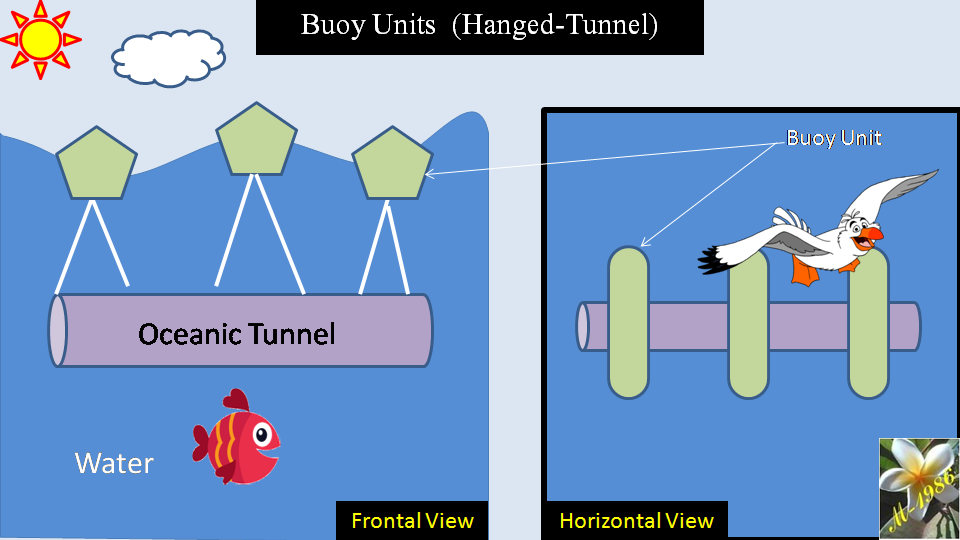

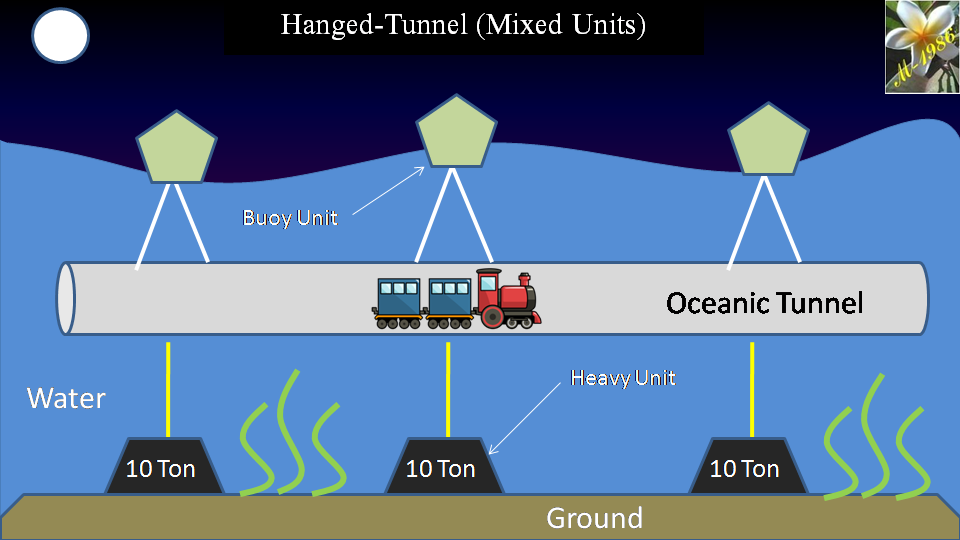

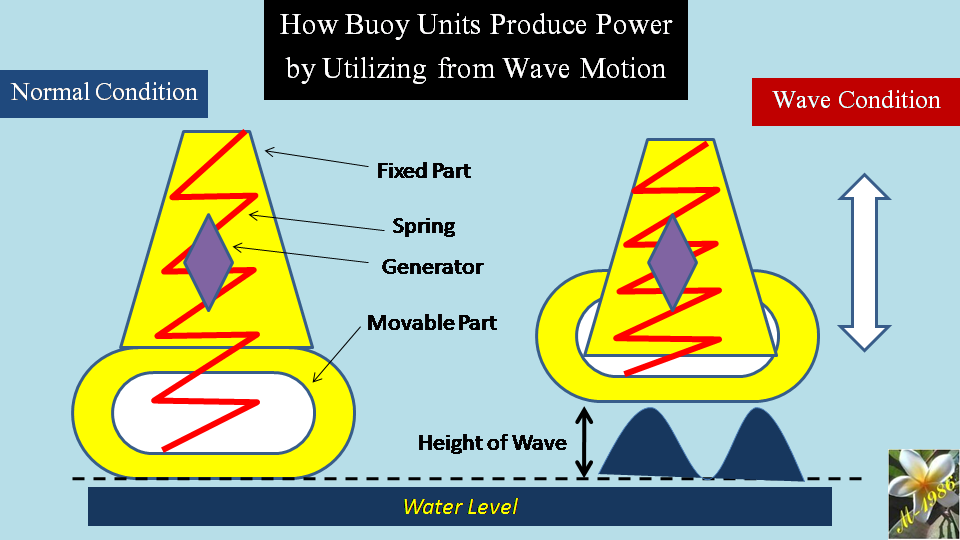

There are 2 ways to hang the tunnel either using; Buoy Unit or the Heavy Mass Unit.

The buoy units as we see in figure (38), will allow boats & ships to cross the tunnel easily & also we can put surveillance equipments on the buoy unit to see what happen around the exposed area of tunnel.

Using heavy mass units has also an advantages as it will increase the security of tunnel too much as it may be difficult to reach-out, by a normal human as we see in figure (39). Of course we may put surveillance equipments there.

Maybe you notice that we can produce electricity by using either from buoy or heavy mass units from the ocean energy (Wave Type). The buoy unit will definitely fluctuated up & down as a result of wave motion, so by designing in specific engineering principles, we may produce electricity easily as we see in figure (40).

If its necessary & for economical reasons, we may using a mixture of buoy & heavy mass units in the oceanic tunnel as we see in figure (41).

#

_(3) Deep Tunnel:_

Risks is surrounded us everywhere unless we keep our eyes open to any probabilities of damaging our property & we spend more money to neutralize the threat.

Hanged-tunnel is good to forbidden human-interference, but we don’t calculate the risks from other intruder who lives in ocean 24 hours. We are talking about big sea-animals such as sharks & whales.

Choosing an oceanic location to build hanged-tunnel which is not have these kind of sea-animal is very rare if it’s not impossible, so we should think about alternative option to avoid such thing threat to our asset.

Deep-tunnel as we see in figure (43) may be the one of the safest method but it’s accompanied with very expensive price of construction, as we faced a high water pressure in the bottom of ocean which effect in the selection of material.

There is nothing to say much about deep-tunnel except we should find creative way to produce electricity inside that long tunnel as solar & ocean energy will be no longer valuable in that deep location.

_(4) Udner-water Tunnel:_

No doubt, digging a tunnel under the ocean may be considered as the safest concept with massive reducing in the construction of tunnel as the pressure of water will not be a problem because the oceanic rocks will maintain the stability between the water & tunnel as we see in figure (44).

Without forget to mention, that it will save us from many risks from either human, big sea animals (e.g. whales) or even the biological or chemical corrosion.

But …, it may take many years or even decades to build such kind of tunnel depend on the distance & kind of rocks beneath the sea-water bed.

Technological developments have seen the transport industry introduce many new, impressive fuel types, touchless technology, robot helpers and autonomous vehicles. However, China is wanting to take that one step further by constructing a 13,000km high-speed underwater railway line, with the line starting in mainland China, running through Siberia, passing under the sea (200km) through the Bering Strait into Alaska and then continuing to Canada, then finally the US.

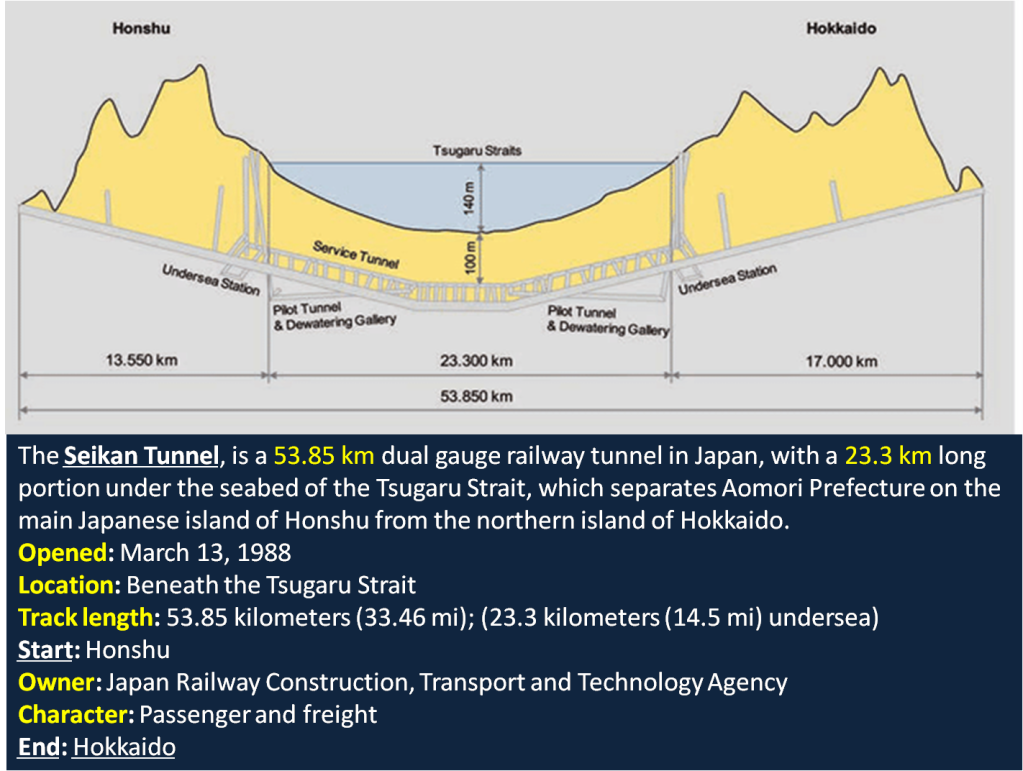

Although this may sound farfetched, underwater railway lines are not too far flung into the future with Japan having its own underwater railway line currently running today named the Seikan railway.

Japan’s 53.85km railway tunnel connects Honshu Island and the Hokkaido Island via track which is located 140m below the seabed. At present the Seikan tunnel is the world’s deepest and longest railway tunnel with approximately 23.3km of the tunnel being located under the seabed making it the world’s longest undersea tunnel.If Japan is able to achieve this impressive underwater train experience, what is standing in the way for China to achieve theirs?

With flight duration from Russia to the United States lasting on average over ten hours, the introduction of the underwater bullet train would enable passengers to travel between the US and Russia in as little as 20 minutes.

Plans for this design were first brought forward in 2014, with reports claiming that China was in advanced talks with Russia who had been discussing construction of a railway line under the Bering Strait for years. The ambitious plan received a great deal of media coverage at the time, with many reporting that it would boost trade links between China, Russia, Canada, and the US.

However, after the initial announcement and excitement not much more was heard about the project with no plans being put in place for construction commencement. Recent reports seen within the South China Morning Post see the plans being heavily criticized due to the budget proposal of $200bn.

That being said, there are still indications that China’s underwater rail project may still go ahead due to China approving the world’s first underwater bullet train in 2018 with aims to demonstrate that high-speed railways are feasible under the sea. [Web-5]

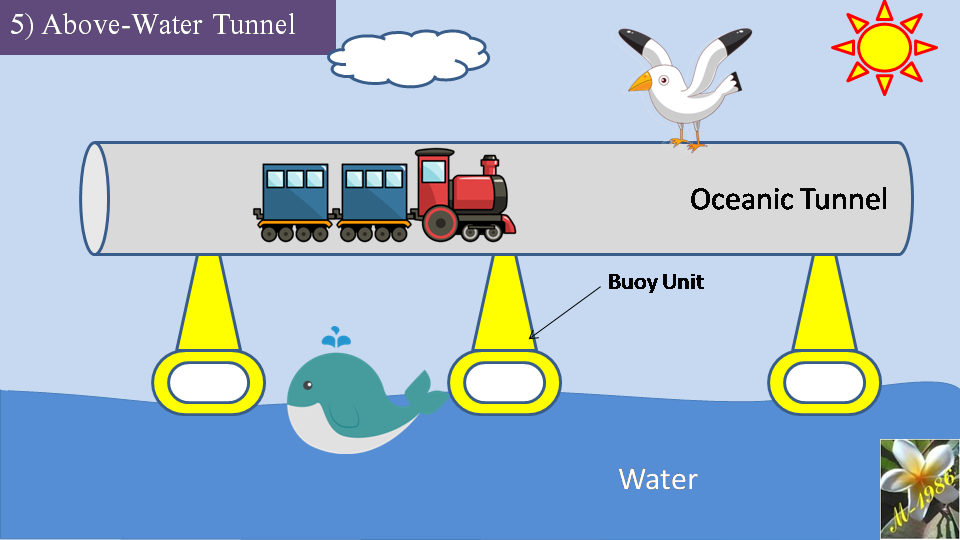

_(5) Above-water Tunnel:_

It may be controversial to say there is difference between it with the surfaced-tunnel type, but it may have some advantages.

As we see in figure (47), the tunnel has been located above the sea-water by using supported buoy units along the tunnel. Obviously, ships & boats may pass through the oceanic tunnel, in opposed to what happen in the surfaced tunnel.

No doubt, that surfaced-tunnel type may be considered as the cheapest type related to the infrastructure cost compared to other but it has a flaw, that it can’t produce electricity from the wave energy. The buoy units in this new type of tunnel have the ability to produce electricity power as we see in figure (48) as there are two parts movable & fixed which they are connected with spring which is attached with unique generator.

I don’t think there are much more to write about it, as I may cover it from all side. It’s obvious types of oceanic tunnel that we could imagine.

#

7) Engineering Analysis of the Closed Oceanic Tunnel:

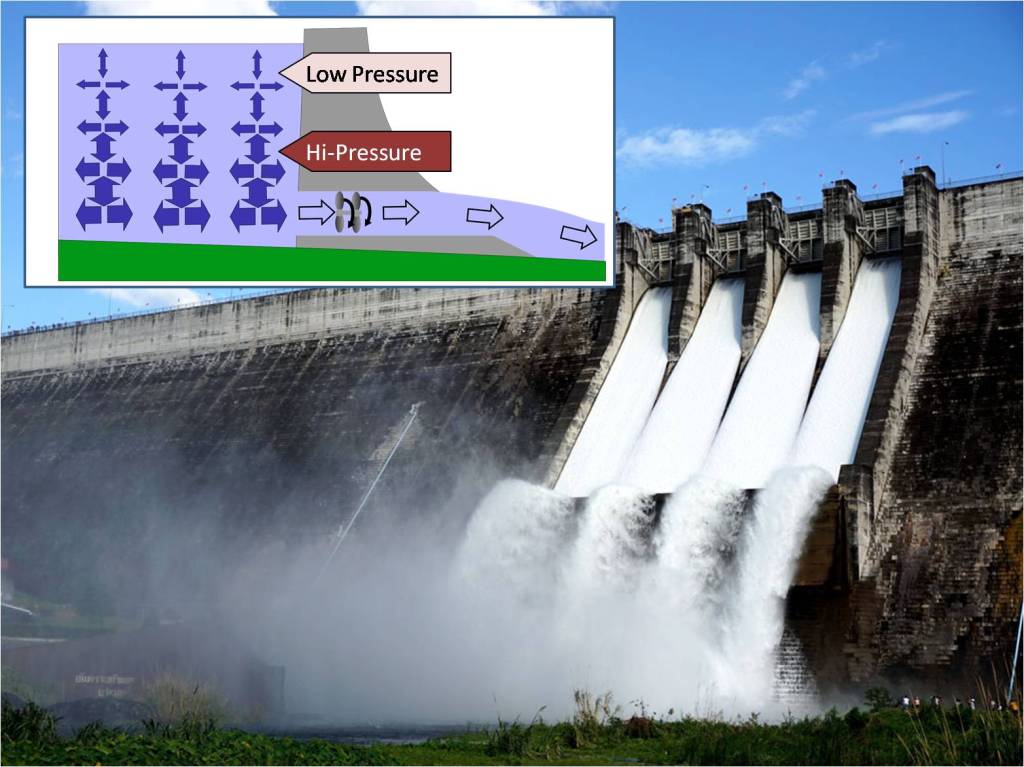

Water pressure is considered a vital element that effect on the design of the oceanic tunnel & it’s determining the reliability, stability & of course, the cost of construction for the tunnel.

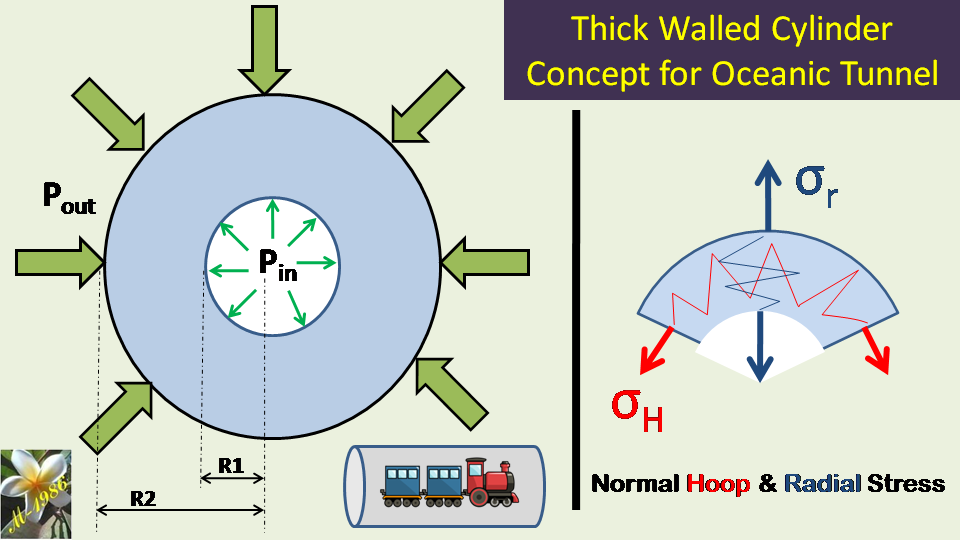

So, here we will talk by engineering principles related to which named as “Thick Walled Cylinders” which may be found in any textbooks of strength of material by assuming that tunnel is in cylindrical shape.

Assume that we have a hollow cylinder with inner “R1” & outer radius “R2”. So, by neglecting the shear stress, we have 2 normal stress acted across the cylinder as we see in figure (50) & they called [Ref-3];

- Normal Radial Stress “σr”.

- Normal Hoop Stress “σH”.

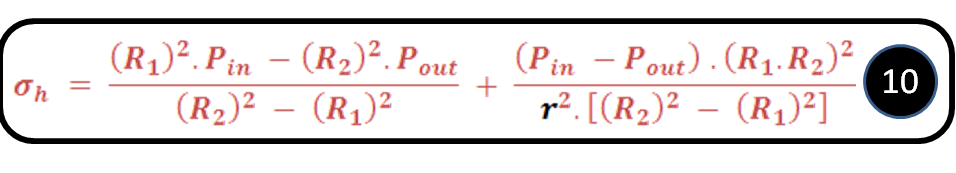

For not get boring, the Equation (9) & (10) represent the radial & hoop stress respectively.

Where :

- r : variable parameter of radius (m)

- Rin: Inner radius (m)

- Pin: Inner pressure (MPa)

- Rin: Outer radius (m)

- Pout: Outer pressure (MPa)

So, let us now examine our 2 exciting equation for some depths.

Before we start, we should mention that we may use the equation (11) to calculate the pressure of water in specific depth “H” to obtain outer pressure on tunnel after we add to the atmospheric pressure (Patm = 0.101325 MPa ) & we will assume the gravity (g= 9.81 m/s2) & density of water (ρ= 1000 Kg/m3). The effect of dimension for tunnel will be neglected for simplicity of solution.

Let us say that we want to put the tunnel, under sea-water level of 10m, so the outer pressure will be:

The inner pressure inside tunnel may be controlled by any ways, but they always prefer to be value equal to atmospheric pressure.

Let us assume that, the inner & outer radius of hollow cylinder is 5 & 5.5m respectively. That’s mean the thickness of cylinder is 0.5m.

So, by substituting above values in equations (9) & (10), we will get:

For Normal radius stress @ r=5 & 5.5m:

By repeating same procedure for radius 5.5m, we will get:

Note: negative Sign means that the type of force is compressive (Not tension)

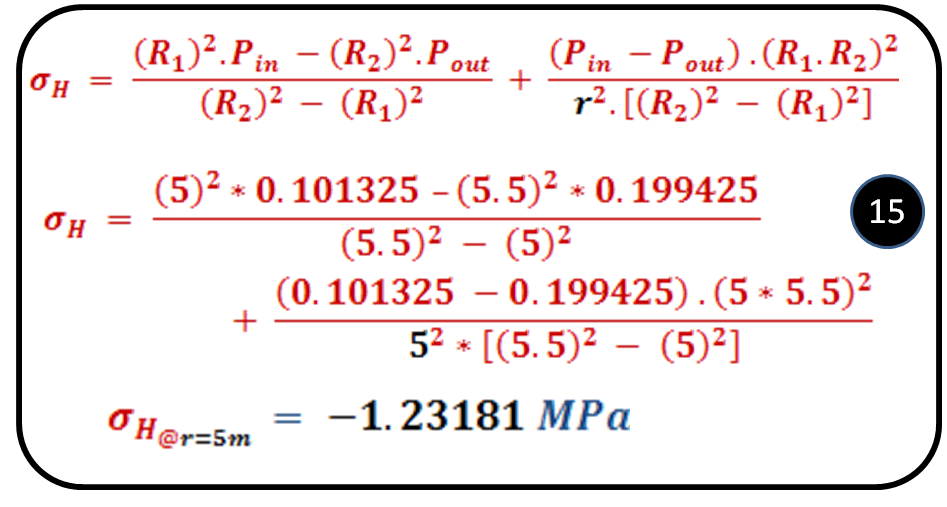

For Normal hoop stress @ r=5 & 5.5m:

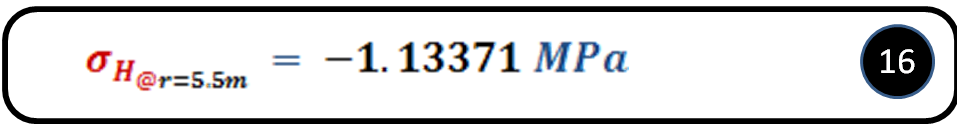

By repeating same procedure for radius 5.5m, we will get:

Note: negative Sign means that the type of force is compressive (Not tension)

You may notice from above results, that maximum value of radius stress is located in the outer side & for the hoop stress is located in the inner side. Figure (51) shows graph curve of radius-stress.

Now, what’s next?

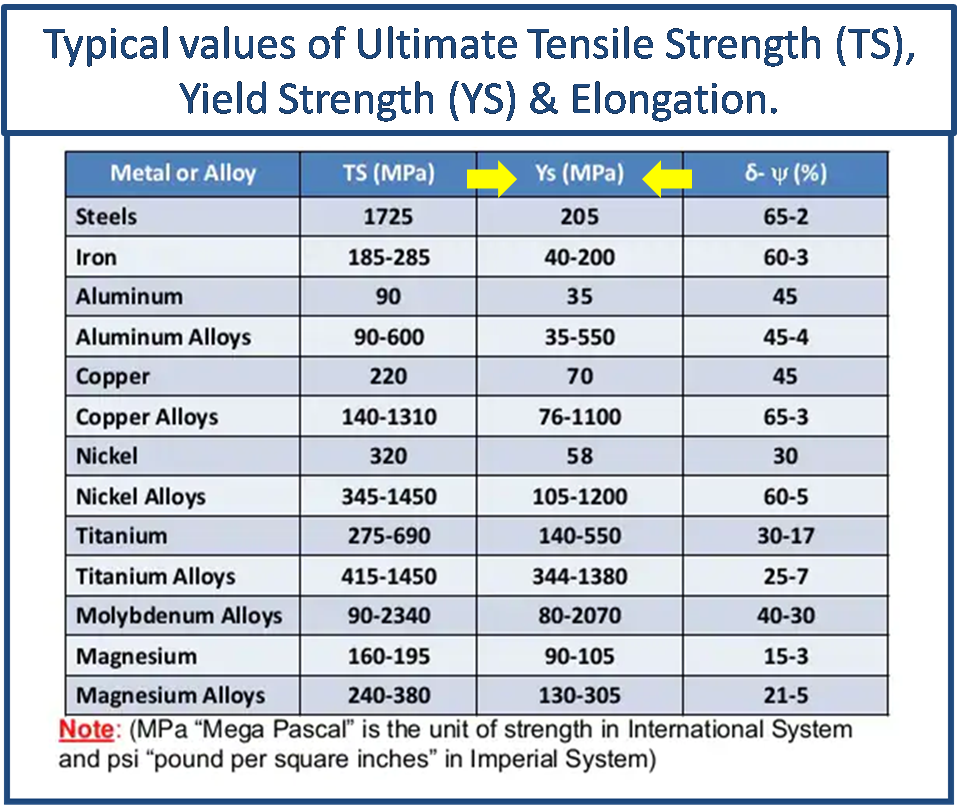

We will take the maximum value of normal stress & compare it with the yield strength of material. As we see in figure (52), yellow star represent the maximum value of stress for transition from the elasticity to plasticity phase.

In majority of engineering application, we should not exceed the yield strength as it’s the point which the material will return back to its original shape before deformation.

Figure (53) shows table of mechanical properties which contains the yield strength (yellow arrow) of common materials.

After that, we select a material depend on the previous table to comply with maximum value of strength & we multiply the volume of tunnel with the price of that material to calculate the cost of construction of the oceanic tunnel. [I know it’s not that simple, but you get the point of how to determine the cost by engineering analysis].

All that calculation is only for depth of 10m ; let us calculate various value of depth to see how the depth may actually affect on the thickness of cylinder.

Table (1) shows the maximum normal radial & hoop stress for depth of 100, 1000 & 2000m for previous case & we give a suggested value for thickness to assure reliability & safety from failure of tunnel under that condition.

You may notice from table (1), that going deeper will increase the normal stress, which eventually increase the cost of construction due to its relationship with the safety thickness for tunnel in that depth.

#

8) Challenges of Oceanic Train Technology:

We saw that spending more money, will definitely make safety for the oceanic tunnel to operate perfectly without any risks of damages, but there is some issues should be solved by creative ways accompanied with economical side.

1) Passing Ships over the Surfaced-Tunnel:

Sometimes, the economical studies shows to us, that we should build the oceanic tunnel by somehow will prevent the ships traffic (if we don’t like to ignore totally the old traditional of maritime transportation) as we see as in example in figure (54) which represent an oceanic tunnel connected between Jibujti (Africa) & India (Asia). It’s very obvious any ships come from the Red Sea or Arab Gulf will not pass it at all.

To solve this challenge, we should make special “Gates”along the surfaced-tunnel to allow ship to pass & closed again as we see in figure (55). It may not be liked by military as it’s kind of a restriction for their way, but in the same time you may control what go in & out of commercial ships without wasting our intelligence resources to survey large areas of ocean.

2) Confined Place for Combustible Vehicle:

If we use vehicle that use fuel, that’s mean we are dealing with chemical combustion process which is need to enrich the tunnel with Oxygen & rid of gas emission such as carbon dioxide (CO2) for closed tunnel as we see in figure (56).

Open types has not problem with previous issue, but if the water gets into the tunnel via higher waves greater than wall of tunnel, then there is a risk of sink for the tunnel due to increase of the weight. So, to solve we should use pump as soon as possible. Definitely, electricity will come from renewable resources (e.g. solar or wave energy).

If you want my suggestion, I would advise to use electric vehicle to transport good safely without worrying about the abundant of oxygen especially if there are many vehicles in the oceanic tunnel in same time.

3) Producing Electricity from Hanged-Tunnel:

We have mentioned earlier, that we can use buoy units in hanged-tunnel to produce electricity. Actually, there were several types of technologies related to what’s named as Wave Energy Converters “WECs” as we see in figure (57). We can use one of them to be attached with oceanic hanged-tunnel & it will works effectively although these technologies has not been reach yet a commercial stage except “Pelamis – The Snake of Sea” type in figure (58), and you may notice it has a match design to oceanic tunnel.

4) Effect of Strong Wave/Storm on Surfaced-Tunnel:

To understand this issue, we may assume that we want to rotate nut by short nut-driver. You may notice or know from your past experience it will be very hard as it wants more force (energy) if the driver not broken. But the situation will change dramatically, if we use long arm nut-driver & it will be easy to rotate the nut as we see in figure (59). So, why that happen?

The main reason related to amount of torque (moment) that has been applied on the nut According to equation in previous photo.

If the force is constant, then the only way to increase the torque is by increasing the distance from the center of rotation to the point of applied force.

What’s the relation between the nut-driver & wave/storm?

Actually, it works similar to the nut-driver.

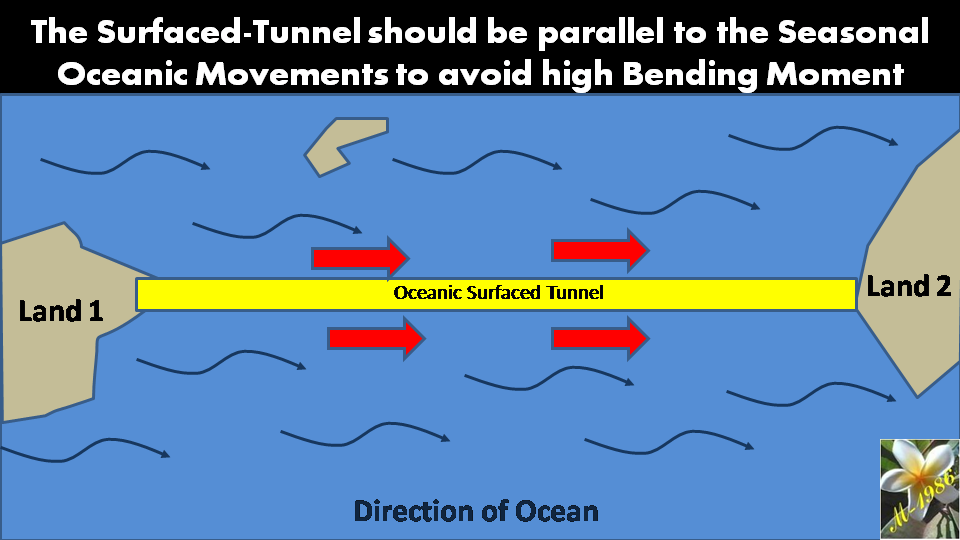

When the surfaced-tunnel built as we see in figure (60), the wave will act like nut-driver to rotate the tunnel or let us use the term of “Bending” the tunnel & try to break into two parts. The bending moment will be on clockwise direction for the left half of tunnel near land 2 & the other will be rotated anti-clockwise direction. The center of rotation will be located on the land or maybe the weakness joint along the tunnel.

Now imagine how much torque (moment) can be when the distance of tunnel reach up to 1000 Km. Something beyond imagination right.

We should find a solution, right?

In my opinion, the design of tunnel must consider the seasonal movements of ocean if we need really to choose that risky zones of high waves & storms & build the tunnel by somehow may not increase the bending moment as possible by make longitudinal path of tunnel parallel to the wave motion as we see in figure (61).

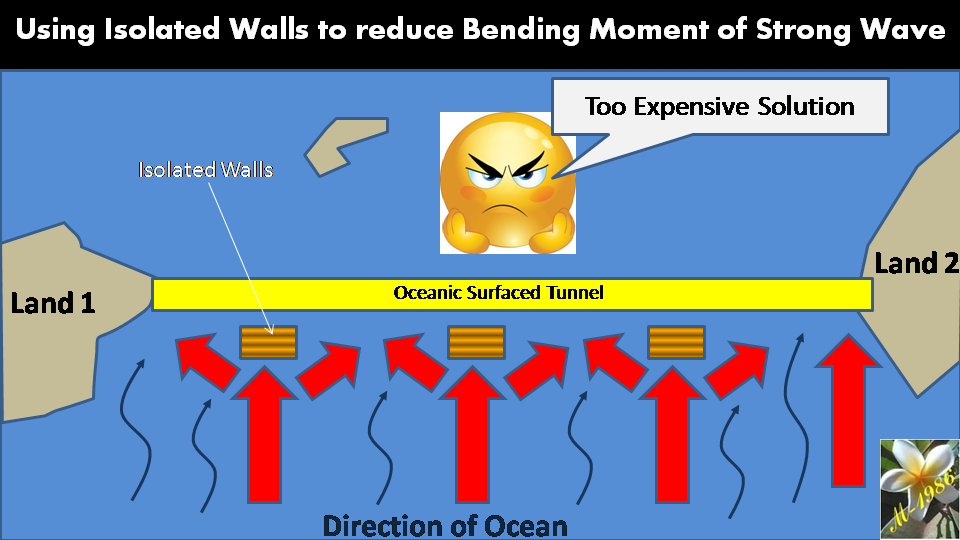

If we don’t have an option to made previous solution, then we should use many isolated walls distributed along the tunnel as we see in figure (62) which definitely will increase the cost of construction, but it will save our property from damage from strong wave or storm by reducing the effect of bending moment.

5) Using Strong Flash-Light to ex Whales from Hanged-tunnel:

I don’t really don’t know if this idea may work, but according to what we know from experience after sleeping, we don’t love light in that moment.

Whales are living inside water for long time

9) Recommendations:

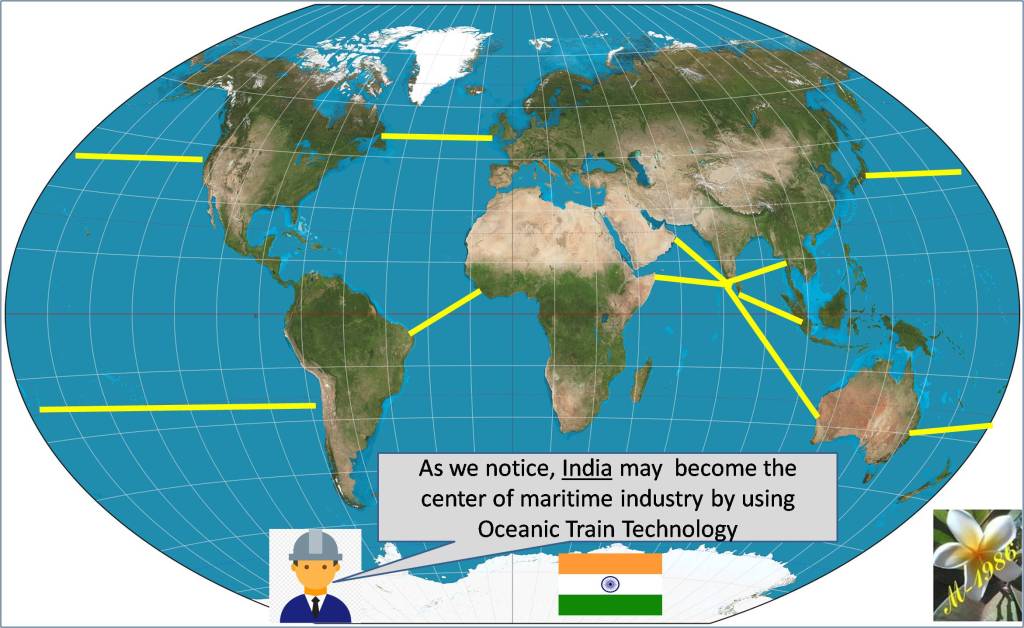

1) I have drawn a hypothetical path for the oceanic tunnels connected between 6 continents on map which I think it’s more cost-effective design as we see in figure (63).

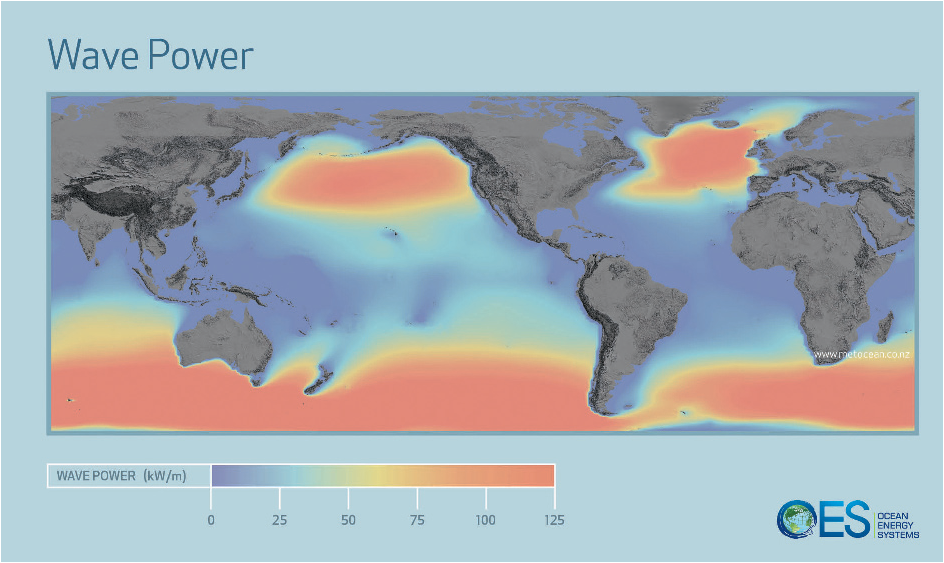

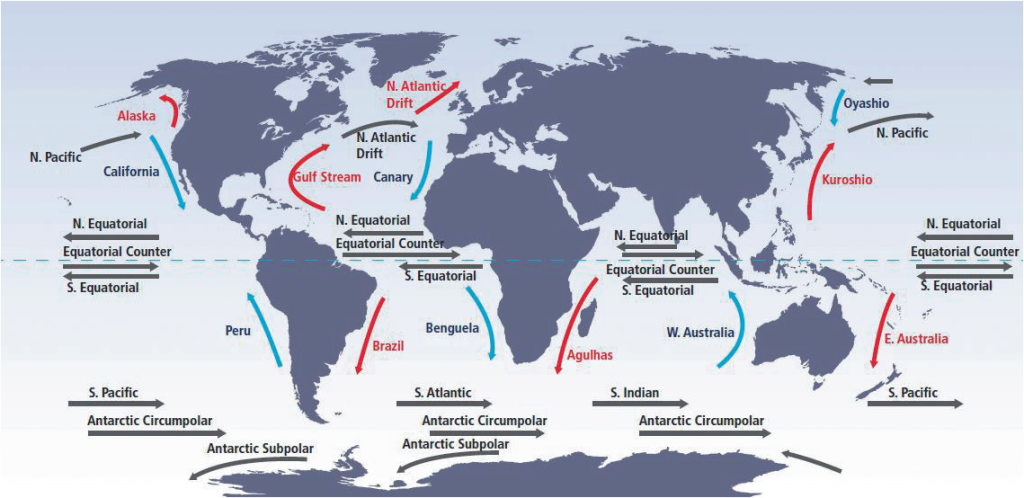

To choose what type of oceanic tunnel should be used (e.g. surfaced, hanged or deep tunnel) is depend on many factors but the important factors is the weather in that area. Below Figures (64) (65) & (66) shows the wave, tidal & current ocean energy that may affect negatively on the stability of oceanic tunnel.

We should proceed carefully as every oceanic zone has its unique features.

############################

2) Building ocean train inside water must take international approval from the countries of the United Nation (UN) because you put a restriction on the ship’s movements over free-seawater & for any military or political disputes it may be vulnerable to destroy by country who like to dominate their reckless behavior for any reason on the decision game to prove their political influence on the world. So, UN should respond quickly & strongly against these kinds of countries as they are threat to the global goods transportation.

Yes, there is no taxation on foreign land & that’s advantage of free-seawater, but we should All be together & protect well the ocean tunnel if want the succession of this promising technology which may change our maritime transportation & help to deliver goods as soon as possible by advancing train technologies.

############################

3) The main controversial question that we should ask ourselves that: if we want to use electric-train as main transportation either in land or seawater for a better place to our beautiful world for complying with UN-Climate Change objectives [or even electric car – (E-Car)].

So, from where we get electricity if we don’t use fossil fuel (Diesel/Gasoline), coal or wood? What I mean, your E-Car in home wants battery to be charged, right?

If you used national-grid of electricity, then the demand will increase beyond the usual for homes & factories. So, to overcome this issue, we should increase our supply from what the power plant feed us & nowadays, majority of them are using gas/liquid fuel or even coal.

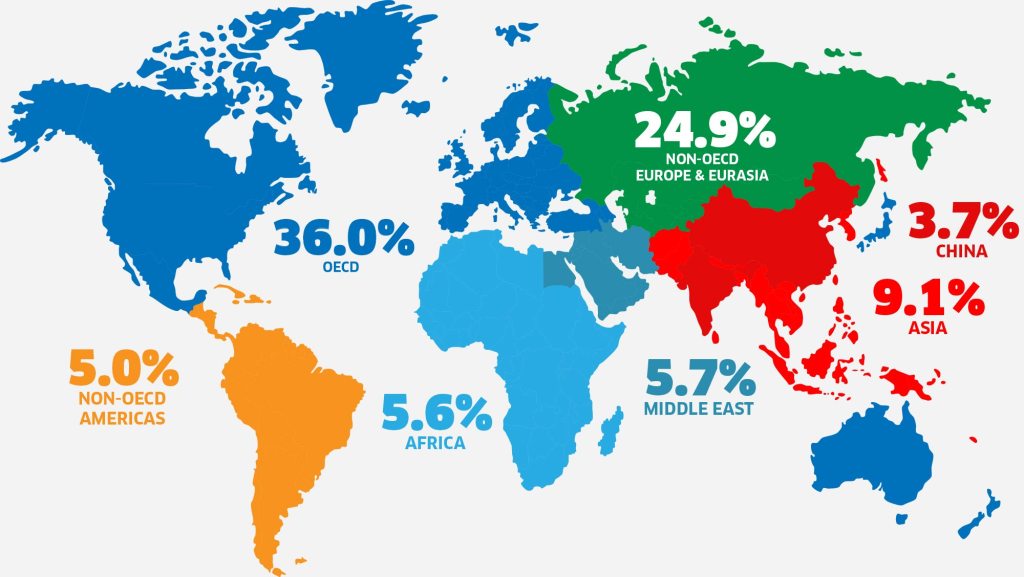

Also, remember our population is increasing & there are some developing countries in Africa & Asia will asking their governments to have electricity for them, which lead to increase in global energy demand due to unexpected regions. Figure (67) shows a percentage of gas demand over the world.

Using renewable energies such as solar & wind energy technologies may be the key of solution, but unfortunately you are talking about expensive investment that may takes decades to deploy globally until we decide to cut-off dependence on the fossil fuel, but I feeling that may not happen even after we consumed all the fossil fuel on earth.

Without forget that Photovoltaic-solar (PV) energy systems suffering from low efficiency, although there still attempts from scientists & researchers to solve this technical problem, but it may need to find another way to absorb the solar energy efficiently by another approach/method rather than PV cell.

Also, we shouldn’t forget the vital factor of Gross Domestic Product (GDP) for some countries are depend on that type of fossil fuel (i.e. coal) & if you want them to reduce their economic stability for the best of humanity, then you should give them a fair compensation of that loss in his annual budget or they will declare a war against everything because those countries will not accept to see other have better life & not for other, by the name “Fighting against Climate Change’

Maybe you noticed in COP 26, which held on Glasgow (UK) recently, that many countries will not keep their promising for the same reason that I have mentioned earlier. They are not ready yet.

We should find another way to solve global energy demands for those countries which may be affected by thinking creativity & make a balance of their human needs & environment equally, with sharing it with all countries depend on their efforts to making our life more easier, comfortable & welfare.

Ocean may still have its secrets that; we don’t yet discover it & probably the ocean energy will be our hope to return back our earth to its origin before the climate change started & neutralize the green house gas (GHG) emissions for once and at all. The oceanic-tunnel may have their potential for it when it’s emerged with other renewable energies technologies.

########

10) References & Websites:

- References [Ref]

Ref-1: Moving Freight: Economy and Atmosphere [PDF Download].

Ref-2: The Review of Maritime Transport 2020, UNCTAD [PDF Download].

Ref-3: Strength of Materials, Part 1: Elementary Theory and Problems – 2nd Edition, By S. Timoshenko – Stanford University (USA) [PDF Download].

- Websites [Web]

Web-1: Marine Vessel Market [https://www.fortunebusinessinsights.com/marine-vessel-market-102699]

Web-2 Train-Wikipedia [https://en.wikipedia.org/wiki/Train]

Web-3: History of Rail Transport- Wikipedia [https://en.wikipedia.org/wiki/History_of_rail_transport]

Web-4: Marin Tests Underwater Hyper-loop Tunnel [https://www.maritime-executive.com/article/marin-tests-underwater-hyperloop-tunnel]

Web-5: China’s Underwater Train: A Pipe Dream or Reality. [https://www.railway-technology.com/features/chinas-underwater-train-a-pipe-dream-or-reality/]